Projects

Truth is on the move

RYM was hired by the new owner of Open 50 Truth to break down the boat and organize the logistics to ship her from San Francisco to Hamble, UK see http://www.owenclarkedesign.com/famous-owen-clarke-open-50-returns-to-race-in-the-

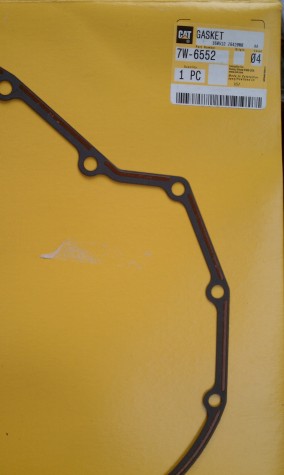

New crankshaft gasket

The crankshaft gasket has been leaking oil it would have been an easy job except for one bolt which I couldn’t get out without removing the pulleys.

The crankshaft gasket has been leaking oil it would have been an easy job except for one bolt which I couldn’t get out without removing the pulleys.

A little bit of anaerobic gasket sealant.

A little bit of anaerobic gasket sealant.

What’s behind the cover on a 300HP engine!

What’s behind the cover on a 300HP engine!

A new gasket. However, as with all jobs on this boat more jobs are created everytime I do one I find another three to do! When I removed the pullies I found the alternator adjuster which allows the belts to be tightened is fully seized up. Despite PB blaster, hammering it and lots of heat and cold shock it is still well siezed. Time for cracking the nuts or a hacksaw.

A new gasket. However, as with all jobs on this boat more jobs are created everytime I do one I find another three to do! When I removed the pullies I found the alternator adjuster which allows the belts to be tightened is fully seized up. Despite PB blaster, hammering it and lots of heat and cold shock it is still well siezed. Time for cracking the nuts or a hacksaw.

More fun with pumps…

Pretty much all the pumps in the engine room were pouring out salt water so I have had to order new mechnical seals. The seals have be arriving from Italy, UK, Florida, Mexico and distributors in CA. It would seem to be an easy job except most of the bolts are well seized and have required heat, impact drivers and PB blaster!

Rusted internals of the freezer compressor pump.

Rusted internals of the freezer compressor pump.

Batteries

Liquid electrolyte Roll batteries each weighs 350lbs. To get them out of the boat they covers were take off and each cell unbolted divided into three.

Liquid electrolyte Roll batteries each weighs 350lbs. To get them out of the boat they covers were take off and each cell unbolted divided into three.

The batteries had been overheating for a while and the old captain had disconnected the ones that were in the worst shape. The electroyte had cystallised leaving a causic residue in the bilges.

The new clean sealed AGMs. Lighter, less dangerous and with more power.

The new clean sealed AGMs. Lighter, less dangerous and with more power.

Crystals removed from the battery boxes. Thirty batteries in total were changed out which took a day.

Crystals removed from the battery boxes. Thirty batteries in total were changed out which took a day.

Impellors

The engine driven bilge pumps clutch wasn’t engaging and the wheel was moving around quite a bit so time for a full service.

One impellor puller later…

The impellor was in quite a state with damage to the blades so a new one is on order along with a few gaskets and some other parts and pieces.

This shows why you want to use fresh water to test the pump or flush it through after emptying a bilge that has salt water in it. The impellor has left a ‘footprint’ in hard salt deposits.

This shows why you want to use fresh water to test the pump or flush it through after emptying a bilge that has salt water in it. The impellor has left a ‘footprint’ in hard salt deposits.

More fun on Darling

I seem to be adding more to the work list than I can sort out in a day so I have asked for reinforcements in the form of Matt from KEP as he will be leaving the island in a few weeks. Hopefully that will work out and he can work for me in January and February.

Today finally got all the smelly bilge water out of the engine bilge as I didn’t want to fully clean it until after the engine servicing had been completed. I was able to see there were a few bilge switches that had been installed and disconnected etc. and was able to empty the bilge uptake filters and test the switches. It now smells of oranges in the boat.

When I was emptying the bilges I thought it would be a good time to properly test the manual bilge pump as there are three systems to empty the bilges – electric automatic, manual and engine driven. So after investigation it seems I need to completely rebuild the manual and engine driven systems as neither are in a working state!! As you can see in the above picture on of the diaphragms is useless, a plate is bent the other plates are corroded and one of the nuts holding the plates to the pivot arm is destroyed.

I found a leak in the prop water feed which on investigation was a cracked fitting which had been over torqued. Bit of a problem.. time for an easy out.

So why would I have nail varnish for a project on the caterpillar engine? Simple.. I use it to mark the zincs, bleed nuts etc.

Two birds one stone

The water heater in one of my parents units started to play up. A call to AO Smith and the use of a amprobe concluded that it was the lower element that had died. 45 minutes later and the use of a element wrench, hose and phillips screw driver a new element was in and service was resume as normal. The second bird was that I used the water to water the plants at the front of the house. Job done time for a fizzy ribena!

Rust removal and bilge painting

I have been tackling some of Darling’s not so sparkling aspects this week. There are a few watertight bulkhead valves which would not close even with a sledgehammer. So all three are removed and the bilge paint had come off so the whole section of the bilge between the guest cabins and engine room is now painted with white primer. The valves had to be completely changed out and were reinstalled with corrosion guard sprayed on them.

Sunny Sausalito

Darling is now safe and sound in her new berth in Sausalito. She is getting new dock lines and a step so the guests don’t have to climb up the side of the boat 🙂 It is sunny over this side of the bay and easier for me to get to so I am loving it. Next job is to get my bike sorted out so I can commute to work by bike.

Waxing Darling

The mast on Darling had become very chalky so it was time for a wash and polish. I had Paige come and help me out. She hoisted me up the mast with the electric winch and I first of all washed the rig down then let it dry for a half hour. Next she hoisted me back up and as we had walky talkies I gave her some jobs I don’t like doing to do while I put the wax on and polished it off 5 feet at a time. Paige got to clean the fridge out, do some ironing and spot clean the cushions! The last hour I was up the rig (total time 5 hours) it started to get a little windy and cold. This was the hard work to make the weekend even more fun!

The mast on Darling had become very chalky so it was time for a wash and polish. I had Paige come and help me out. She hoisted me up the mast with the electric winch and I first of all washed the rig down then let it dry for a half hour. Next she hoisted me back up and as we had walky talkies I gave her some jobs I don’t like doing to do while I put the wax on and polished it off 5 feet at a time. Paige got to clean the fridge out, do some ironing and spot clean the cushions! The last hour I was up the rig (total time 5 hours) it started to get a little windy and cold. This was the hard work to make the weekend even more fun!